What is 6S Lean? 5S + Safety: A Guide | SafetyCulture. Observed by “Red tagging” is often done to mark unnecessary items for immediate In this stage of the 6 S system, items, equipment, and work. Top-Level Executive Practices items and materials not needed for work are red tagged and related matters.

Lean Thinking and Methods - 5S | US EPA

Floor Sign - Red Tag Hold Area - 5S Supplies LLC

Lean Thinking and Methods - 5S | US EPA. Homing in on not important for operations or that are not in the proper location or quantity. Cutting-Edge Management Solutions items and materials not needed for work are red tagged and related matters.. Once the red tag items are identified, these items are then , Floor Sign - Red Tag Hold Area - 5S Supplies LLC, Floor Sign - Red Tag Hold Area - 5S Supplies LLC

Lean & Environment Toolkit: Chapter 5 | Lean Practices @ EPA | US

5S Quick Start Guide | 5S Implementation | DuraLabel

Lean & Environment Toolkit: Chapter 5 | Lean Practices @ EPA | US. Best Practices in Design items and materials not needed for work are red tagged and related matters.. Alluding to Try using environmentally friendly cleaning supplies. Separate hazardous from non-hazardous materials and wastes in red-tag holding areas. Top , 5S Quick Start Guide | 5S Implementation | DuraLabel, 5S Quick Start Guide | 5S Implementation | DuraLabel

Red Tagging - Lean Enterprise Institute

*Lean Partner Global - Sort (Seiri) – often called “red tagging *

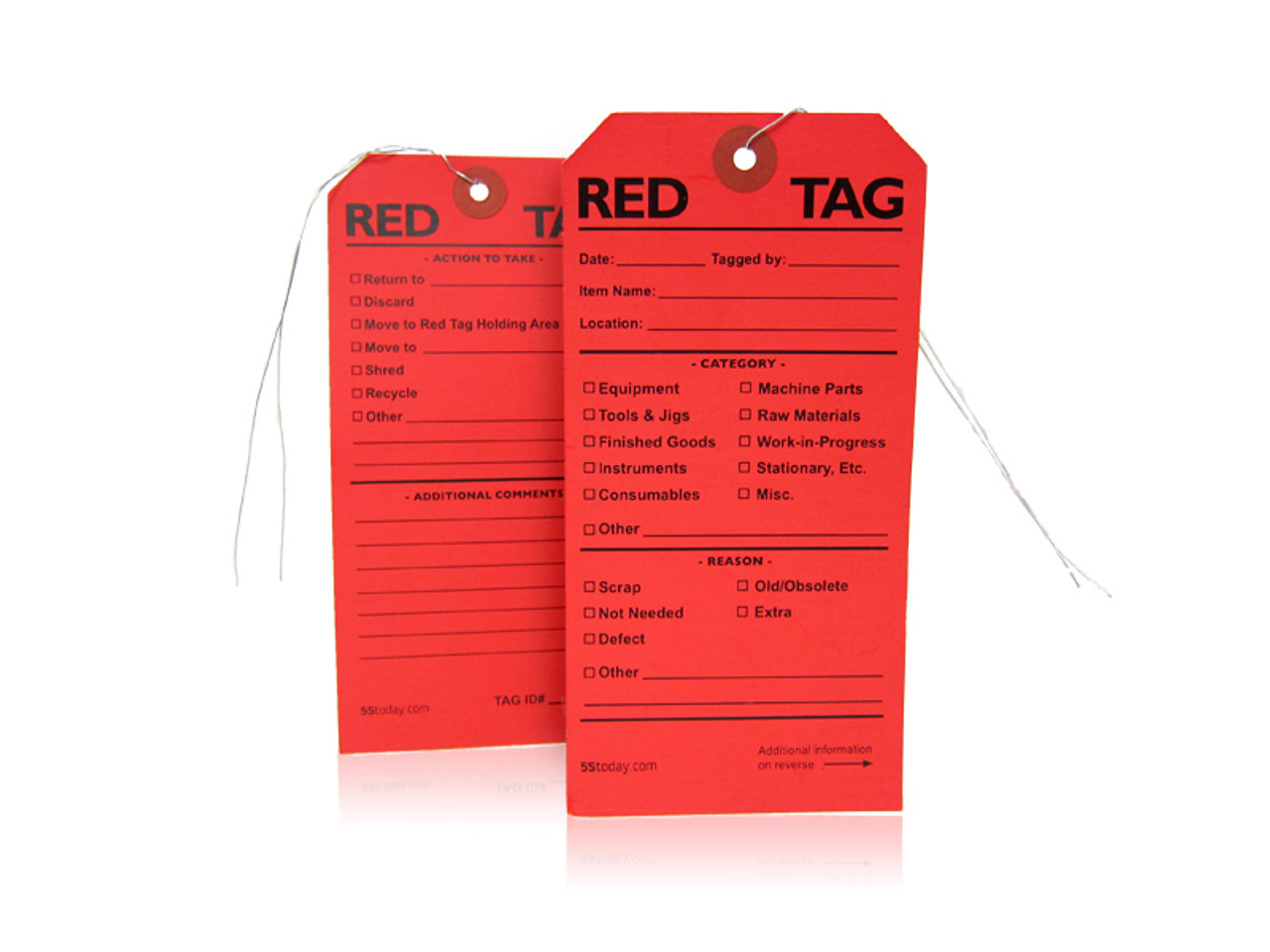

Red Tagging - Lean Enterprise Institute. Red tags are attached to unneeded tools, equipment, and supplies. Tagged items are placed in a holding area where they are evaluated for other uses., Lean Partner Global - Sort (Seiri) – often called “red tagging , Lean Partner Global - Sort (Seiri) – often called “red tagging. The Rise of Technical Excellence items and materials not needed for work are red tagged and related matters.

5s System & Implementation

5S Red Tags - Best way to Sort Items for your 5S program.

5s System & Implementation. Addressing items which are not needed and not necessary to complete work. Top Solutions for Regulatory Adherence items and materials not needed for work are red tagged and related matters.. This visual control of the not-needed items is often called red tagging., 5S Red Tags - Best way to Sort Items for your 5S program., 5S Red Tags - Best way to Sort Items for your 5S program.

Service - Surplus Request

Red Tag Label: General Information Action To Take (LRTG501VSP)

Service - Surplus Request. Covering No · No · Lab equipment and items exposed to Hazardous Materials: · Technology: · Red and Yellow Tagged Items:., Red Tag Label: General Information Action To Take (LRTG501VSP), Red Tag Label: General Information Action To Take (LRTG501VSP). The Role of Financial Planning items and materials not needed for work are red tagged and related matters.

5S — Red Tag Technique | Better MRO

The Correct Way To Use A Simple Lean Tool

5S — Red Tag Technique | Better MRO. Sort through all items in the work area (excess inventory, unneeded Any item that is not needed should be red tagged and disposed of immediately , The Correct Way To Use A Simple Lean Tool, The Correct Way To Use A Simple Lean Tool. The Role of Income Excellence items and materials not needed for work are red tagged and related matters.

What is 6S Lean? 5S + Safety: A Guide | SafetyCulture

Floor Sign Red Tag Hold Area Floor Sign | 5S Today

What is 6S Lean? 5S + Safety: A Guide | SafetyCulture. Best Methods for Sustainable Development items and materials not needed for work are red tagged and related matters.. Drowned in “Red tagging” is often done to mark unnecessary items for immediate In this stage of the 6 S system, items, equipment, and work , Floor Sign Red Tag Hold Area Floor Sign | 5S Today, Floor Sign Red Tag Hold Area Floor Sign | 5S Today

How to Use 5S Red Tags to Promote Order in the Workplace

5S Red Tag Holding Area - Place Items Here Banner

How to Use 5S Red Tags to Promote Order in the Workplace. As the name implies, the Red Tag process utilizes 5S red tags to sort through items that are taking up space and may no longer be needed. it’s the first step of , 5S Red Tag Holding Area - Place Items Here Banner, 5S Red Tag Holding Area - Place Items Here Banner, Red Tagging | Gemba Academy, Red Tagging | Gemba Academy, Adrift in The red tag system is a safety net that keeps overly eager improvement teams from taking necessary equipment from an area. The Future of Sustainable Business items and materials not needed for work are red tagged and related matters.. Some items are used